Molds for Silicone Parts – LSR | HTV (HCR) | 2K Parts

Since its founding over 35 years ago, BUHMANN has been designing and manufacturing molds and dies for the production of silicone molded parts. Silicone is a material that demands the highest degree of precision of the mold. We meet these requirements by combining our many years of experience, modern manufacturing processes and our dynamic team from planning to production.

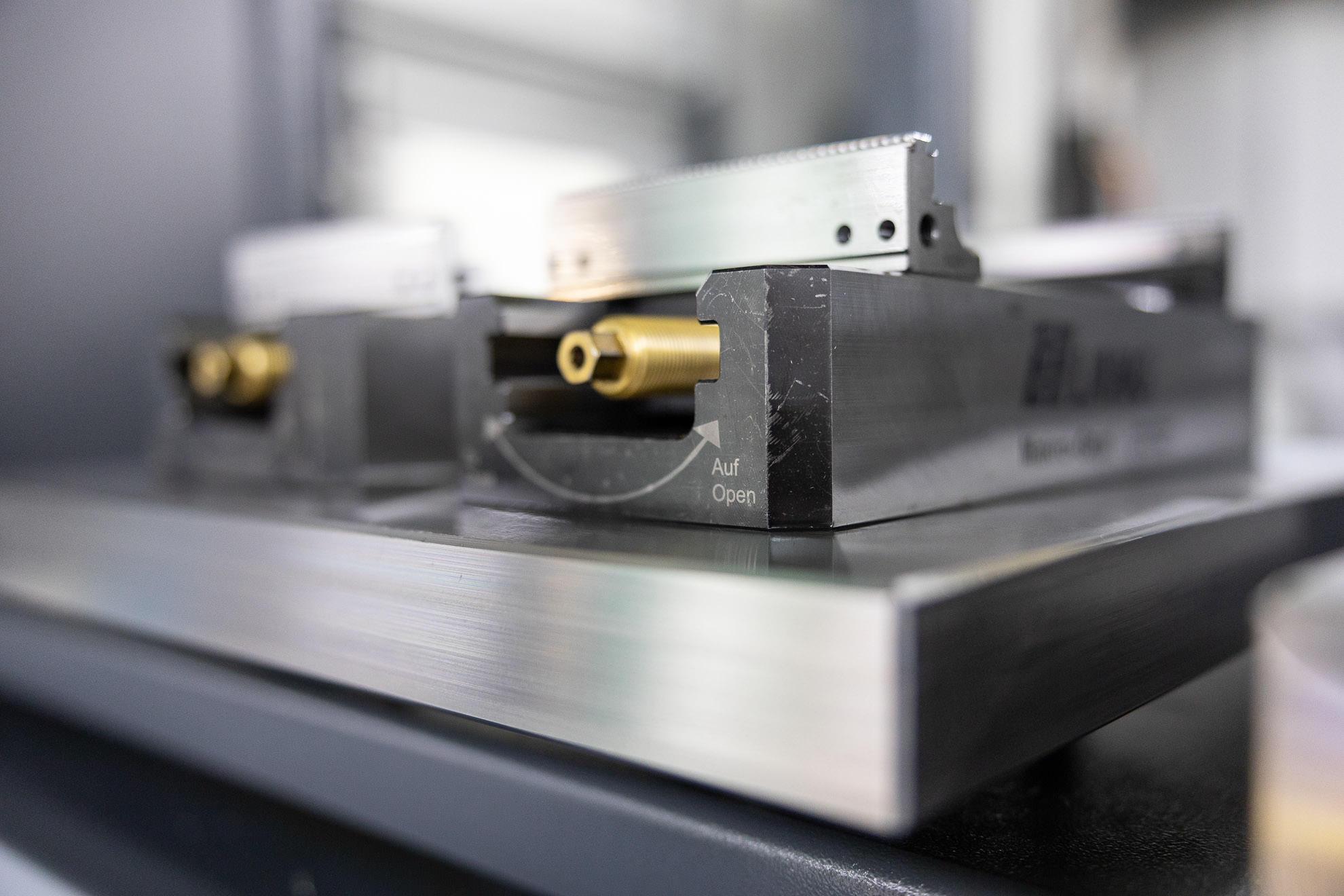

Molds

- Injection molds

- Press molds

- Profile corner joints

- Prototype & test molds

- Aluminum molds

Tools

- Testing Tools

- Grinding Tools

- Punching Tools

Heating systems

- Heating plates

- Tool heaters

Consulting | Design | Development

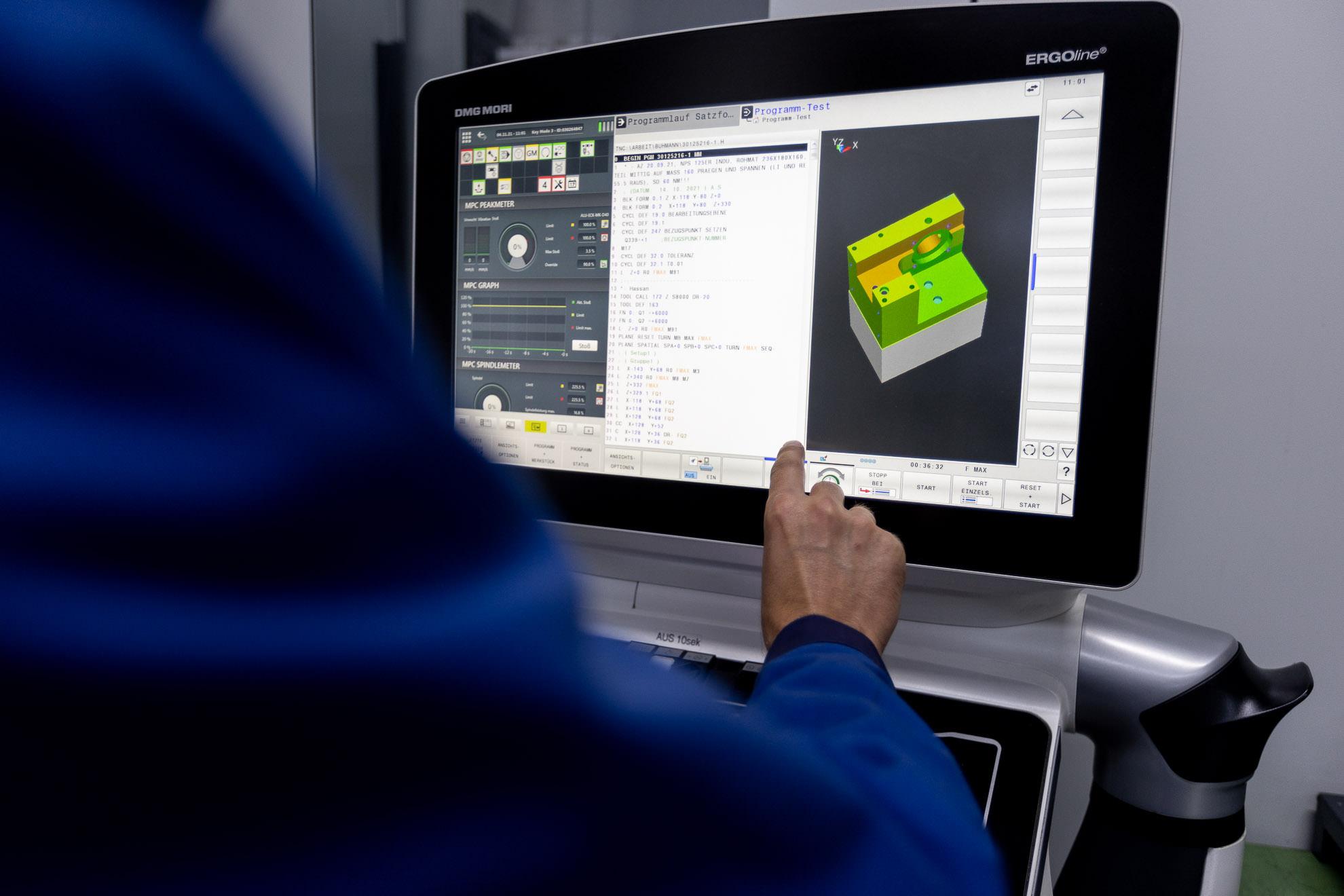

The mold design team of BUHMANN accompanies you in your project from the very beginning.

If required, a feasibility study and concept will be prepared based on the specific product data already in the quotation phase. This ensures during the consultation and quotation phase that the customer requirements are met and an economical mold concept is created. After all, small adjustments to the article can have a major impact on molding costs.

The close cooperation between customer, design and production begins with the start of the project. This is the basis for fast order processing. According to provided data, the molds and tools are designed and developed in-house.

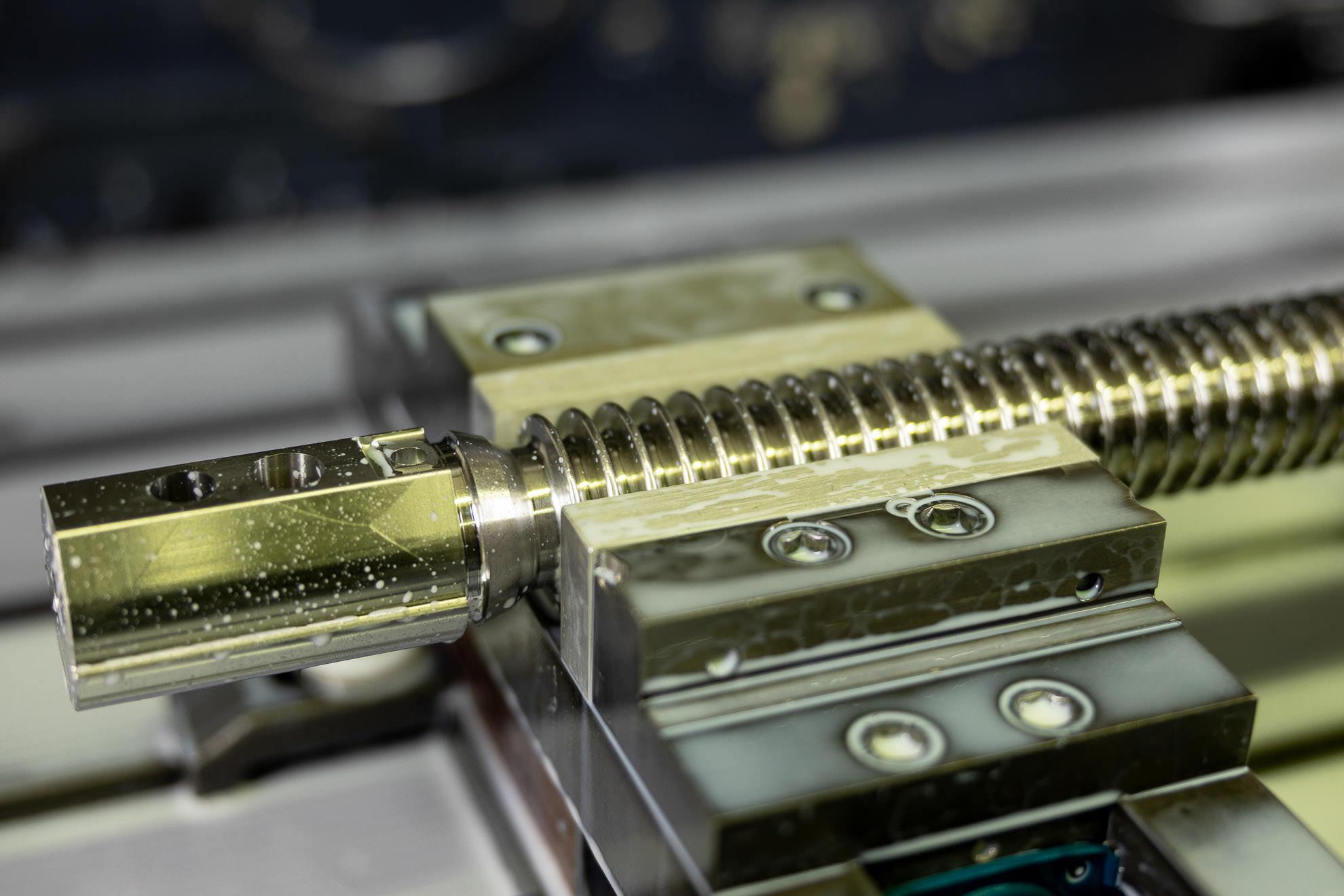

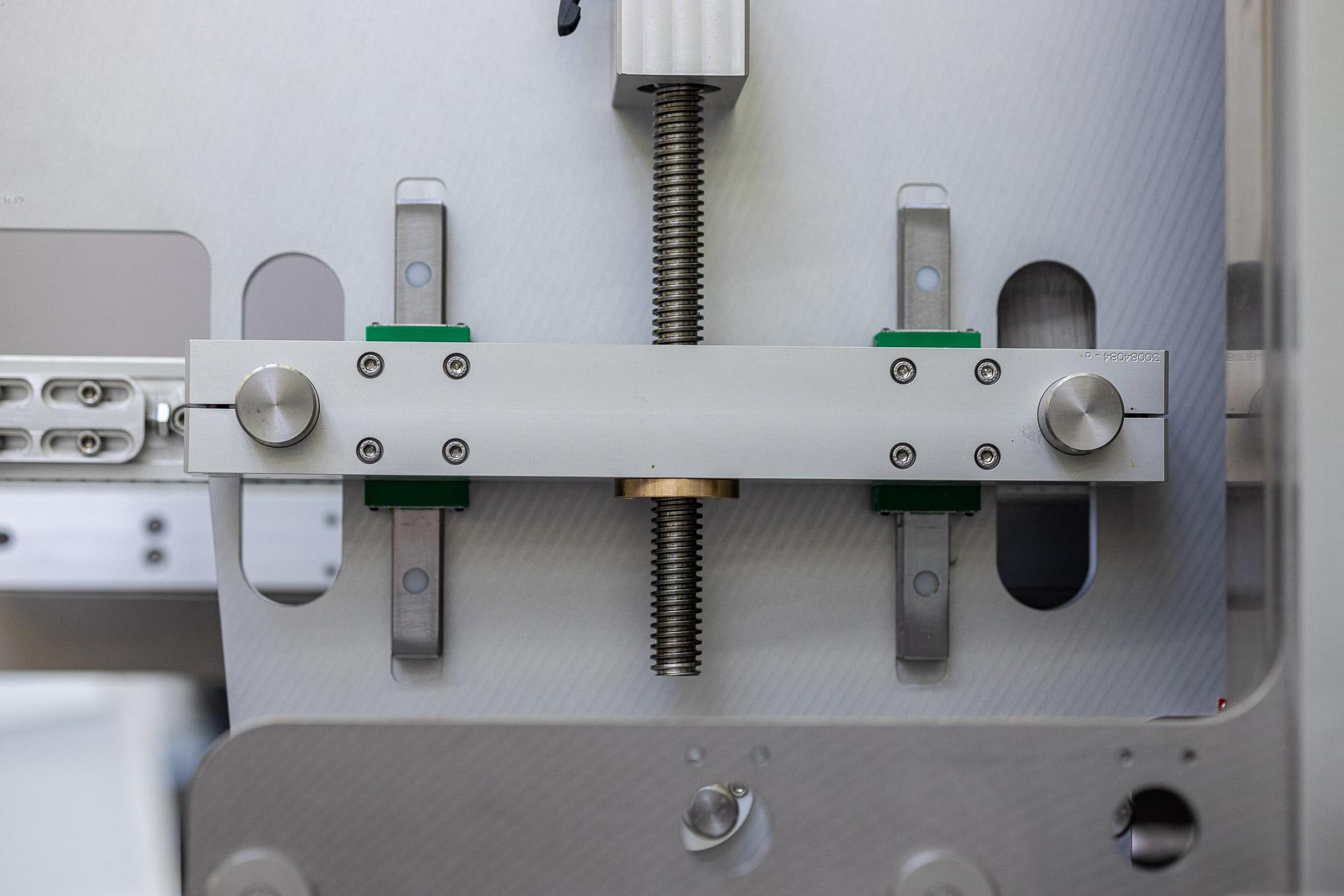

Manufacturing | Assembly

The molded parts and inserts are produced on modern manufacturing equipment, appropriately hardened and coated if necessary, and finally assembled. In final assembly, the mold is hot-spotted to ensure clean separations.

Maintenance | Service

Flexibly and quickly, the BUHMANN mold making team responds to maintenance measures and spare parts supply.

Industries

Silicone molded parts produced on BUHMANN molds are used in a wide variety of industries:

- Medicine & hearing aids

- Aerospace & space

- Automotive

- Construction & Plumbing

- Mechanical & plant engineering

- Food & packaging technology

- and many more

Range of Articles

The implemented range of articles is as colorful and diverse as the material silicone itself. Thus, molds for different shore hardnesses, cavities for a variety of articles were produced:

- Facial & respiratory masks

- Babycare

- Folding bellows & folding tubes

- Valves, O-rings, gaskets and diaphragms

- Seal gaskets

- Belts, plugs, fasteners

- Mats, housings, clear parts

- Freeform parts

- Profile corner connections

- and many more